There are so many ways of getting a finishing on wood. Brushes, rags, rollers, and spray guns, to mention a few, can all be used. With the different types of wood finishing applicators, how do you know which one is right to use?

The key to a professional finishing job is using the right applicator and application method. This article will help you pick the right tool for the job. Check out our best deck stain applicators.

Brushes

Brushes are the most common finishing applicators around. Choosing a good quality brush for finishing is important if you want better results. A good brush should hold more finishing material and spread it smoothly. It should also be easier to use and more durable.

You can choose from three types of brushes to apply wood finishes. These are natural bristle, synthetic bristle, and foam. There are also paint pads which can be assumed to be a type of brush because their application is the same.

Left to right: chisel-edged, natural-bristle brush; chisel-edged, synthetic-bristle brush; square-edged, synthetic-bristle brush; foam brush; paint pad.

Natural bristle brushes, like normal hair, become softened and uncontrollable in water. Therefore these brushes are not good for water-based stains and finishes. However, natural bristle brushes are good for solvent-based oils and less thick finishes. Most of the best natural bristle brushes are made from the hair of Chinese hogs.

Synthetic bristle brushes are made from nylon, polyester, or both. A synthetic brush will perform well for water-based finishes, varnishes, paints, and other thicker finishes.

Foam brushes will produce minimal or no brush marking when using them. However, they can leave a distinct ridge with each brush stroke, especially when more finish is applied. Denser foam brushes are better and will offer superior performance compared to less dense foam brushes. Because they are cheaper, foam brushes can be used and disposed of afterward. Avoid using foam brushes in lacquer thinner because they will dissolve.

Paint pads are thousands of short filaments attached to a foam backing. Their performance is much like foam brushes. However, they are only useful for large and flat surfaces because they are mounted on a flat metal or plastic holder. Their large sizes make them good for finishing floors. Like foam brushes, don’t use paint pads with lacquer.

Rags

Rags are a wood finisher’s stable applicator and can easily work on different finishes. For the best results using rags, they should be made of cotton. Other materials for synthetic rugs, e.g., polyester, are not very absorbent.

If you’re working with a finish that does not contain water, you can get away with substituting cloth rags with paper towels. For finishes containing water, you can substitute rags with Scott rags, which do not fall apart easily when wet.

If you’re working with a finish that does not contain water, you can get away with substituting cloth rags with paper towels. For finishes containing water, you can substitute rags with Scott rags, which do not fall apart easily when wet.

You can easily make a rubbing pad from a rag by folding a cloth and wrapping it tightly with another cloth. You can also wrap a piece of clean cotton wool in a cloth and use it. When making a rubbing pad, ensure the bottom is smooth and wrinkle-free.

Rubbing pads are great for rubbing finishes and French polishing. You can apply any film finish and produce good results with fewer marks than using just a folded or wadded cloth.

Rollers

Rollers are another applicator to deliver a finish faster on a wood surface. They are good for stains, oils, and varnishes. While they are suitable for different finishes, we recommend using rollers where you do not need a smooth finish. Be careful of overapplication and overlapping when applying finishes with a roller.

For rougher surfaces, like older wooden decks, consider choosing a thicker nap size (3/4-inch or thicker), which will go between the cracks and deliver a paint or stain. For smoother surfaces, a thinner nap size will do. Rollers are also good for applying wood finishes to multi-directional floors, such as parquets.

T-Bars

A T-bar is a professional applicator great for applying finishes to floors. Their design does not limit their use to only open floor areas, but you can also use them easily for awkward spaces like around doors.

The Duratool T-Bar Applicator is easy to work with, and you can attach a standard pole. It makes spreading a wood finish easy and makes a time-consuming job go much faster.

While T-bars are great for applying different floor finishes, they work best and are recommended for water-based floor finishes. Using a T-bar can help you avoid lap marks, tun marks, and uneven sheen levels resulting from finishing a bigger area.

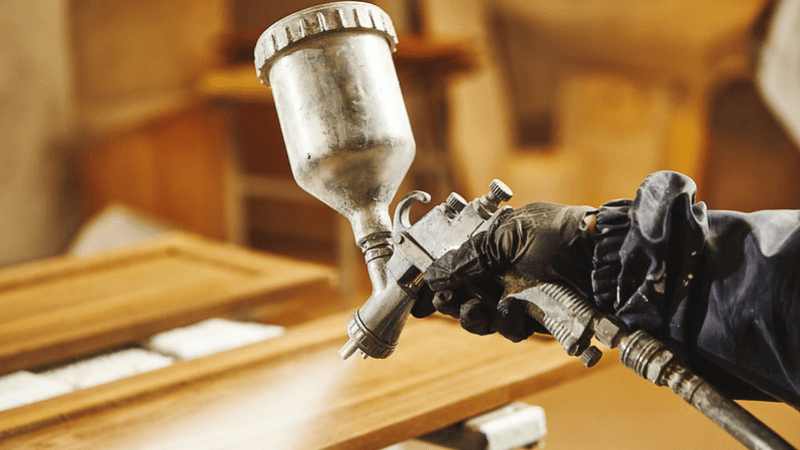

Spray Guns

A spray gun is a faster and easier way to apply a finish than other methods, like brushing. Spray guns work by atomization. This turns paint, stain, or other liquid materials into a fine mist and then propels it onto the surface. All spray guns will work with almost all wood finishes except the thicker ones.

While they offer a faster and easier way of applying wood finishes, spray guns also have disadvantages. They will cost you more and create more waste because of overspray and bounce-back. You will also need proper equipment when spraying finishes to avoid health complications.

There are different types of spray guns you can choose from. If you do not do a lot of spraying, you can choose either conventional, turbine HVLP or compressor HVLP. These are cheaper to buy. If buying a new gun, choose between a turbine HVLP and a compressor HVLP. See the best sprayers for cabinets and furniture.

Apart from spray guns, you can achieve the same results by using aerosols. These are ideal for smaller projects and touchups. You will also find different popular finishes packaged as aerosols in different sheens. These finishes are the same as the ones you’d spray, but they are thinned more, and you will have to spray at least two times to get a thicker film as you would with a spray gun.